Customized mechanical engineering industry support for your unique challenges.

Customized mechanical engineering industry support for your unique challenges.

Blog Article

Leading Tips for Effective Electric System Troubleshooting

Troubleshooting electric systems calls for a methodical method, based in a thorough understanding of electrical concepts and safety and security protocols. The subtleties of effective troubleshooting prolong beyond mere technological expertise; recognizing exactly how to document searchings for and prioritize security can substantially influence end results.

Understand the Fundamentals

Understanding the essentials of electrical systems is important for effective troubleshooting, as a solid structure allows technicians to detect and settle problems much more successfully. A thorough understanding of electric principles, such as voltage, present, resistance, and power, is essential in identifying the origin triggers of problems. Voltage is the electric potential difference that drives current via a circuit, while resistance opposes the flow of existing, influencing the general performance of the system.

Familiarity with circuit components, consisting of resistors, capacitors, diodes, and switches, is also critical. Each element plays a distinctive function in circuit behavior and can affect performance when malfunctioning. In addition, recognizing collection and parallel circuit setups is essential, as these arrangements affect the distribution of voltage and existing within the system.

Professionals need to be aware of potential risks, such as shock and brief circuits, to apply safe troubleshooting practices. By grasping these fundamental concepts, specialists enhance their capability to carry out efficient diagnostics and repairs, eventually leading to improved efficiency and dependability of electric systems (electrical system troubleshooting).

Gather Necessary Equipment

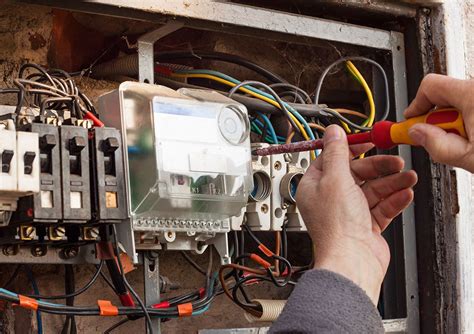

Effective troubleshooting of electric systems calls for the appropriate collection of devices to detect and settle problems precisely. A well-equipped service technician can dramatically boost efficiency and performance in recognizing problems. Essential tools consist of a multimeter, which gauges voltage, present, and resistance, permitting specific evaluations of electric elements. Secure meters are also beneficial for gauging existing without separating the circuit, making certain security and benefit.

In addition, insulated hand devices such as screwdrivers, pliers, and wire pole dancers are crucial for safely adjusting electric links. It is also a good idea to have a circuit tester accessible to validate the existence of voltage in electrical outlets and cables. For even more facility systems, a thermal imaging electronic camera can aid spot overheating parts, suggesting prospective failures.

Comply With an Organized Strategy

Having collected the proper devices, the following step in troubleshooting electrical systems is to comply with an organized approach. A systematic strategy ensures that specialists can determine mistakes successfully and precisely, minimizing downtime and avoiding unnecessary repair services.

Begin by examining the system's schematic layouts and specs. Understanding the layout and operational parameters will provide context for identifying concerns. Next, separate the issue area by making use of a procedure of removal. This includes monitoring each part systematically, starting from the power source and functioning in the direction of the lots.

Use screening equipment, such as multimeters and oscilloscopes, to gather objective data concerning voltage, present, and resistance at various points within the system. This empirical evidence will certainly guide your troubleshooting initiatives and help to confirm or eliminate potential reasons of failing.

Additionally, take into consideration environmental aspects that might influence the system's performance, such as temperature level look at here changes or wetness ingress. A comprehensive inspection of wiring, links, and parts will certainly make certain that all opportunities are made up.

Record Your Searchings For

Extensive documents is essential in the fixing procedure of electric systems. Accurate records enhance the efficiency of identifying reoccuring issues and facilitate interaction amongst staff member. Each searching for needs to be meticulously kept in mind, including symptoms observed, examinations conducted, and the outcomes of those examinations. electrical system troubleshooting. This method not only aids image source in comprehending the origin of the problem however likewise acts as a recommendation for future repairing efforts.

In addition, keeping a log of components replaced or repair services executed is important. This info supports stock monitoring and can assist evaluate the long life and reliability of details parts.

Ultimately, the documentation procedure ought to be thorough yet concise, enabling simple retrieval and review - electrical system troubleshooting. By prioritizing thorough paperwork, technicians can develop an important data base that not just aids in present troubleshooting however additionally equips future maintenance efforts, thus boosting general system dependability

Prioritize Precaution

Acknowledging the inherent threats connected with electrical systems is critical for guaranteeing security throughout troubleshooting. Electric shock, burns, and equipment damages are just a few of the potential hazards that technicians deal with. Prioritizing precaution is not just a legal commitment but likewise an ethical essential that safeguards both the service technician and the surrounding setting.

Before beginning any troubleshooting task, technicians should don appropriate individual safety devices (PPE), including shielded handwear covers, safety glasses, and flame-resistant clothes. Making certain that the workspace is completely dry and totally free of clutter can substantially minimize the danger of mishaps. It is necessary to de-energize circuits before starting any kind of work, verifying that they are not live with the usage of a multimeter or voltage tester.

Establishing clear communication procedures with employee is additionally crucial; this ensures that everybody is my website mindful of prospective risks and the standing of the electrical system being serviced. Last but not least, having an emergency action strategy in position can prove very useful in case of an occurrence. By prioritizing safety and security procedures, service technicians can successfully alleviate threats and promote a much safer work environment.

Final Thought

Effective electrical system repairing depends on a detailed understanding of basic concepts and a methodical technique. Prioritizing safety and security steps guarantees the well-being of individuals involved and the integrity of the electrical system.

Report this page